A warm world where people and technology coexist!

Business Field

MES Solution

- Maximize productivities by recording/managing all production activities of the factory with data until finished products are available from the product order.

Control SW

- It is a control SW that controls process devices to industrial equipment and devices (semiconductors, LCD, LED, SOLAR, etc.).

- Provides control and operational solutions for new equipment as part of the factory automation support solution.

Application SW

- Develop a various S/W needs for the company and factory.

Developing the Product Family of Servers

- Development of WEB/Mobile S/W utilizing Server and Light ERP Solution for Business Support.

Consulting Support

- Consulting support for Smart Factory support projects/BPM analysis at production sites

Companies that wants to receive Smart Factory support

Companies that need analytical solutions to maximize productivity

Companies that want to produce management indicators at the level of large enterprises

Companies that want to manage reports based on a variety of data

Companies that want to manage its production history

Companies that want to use production data in a variety of ways

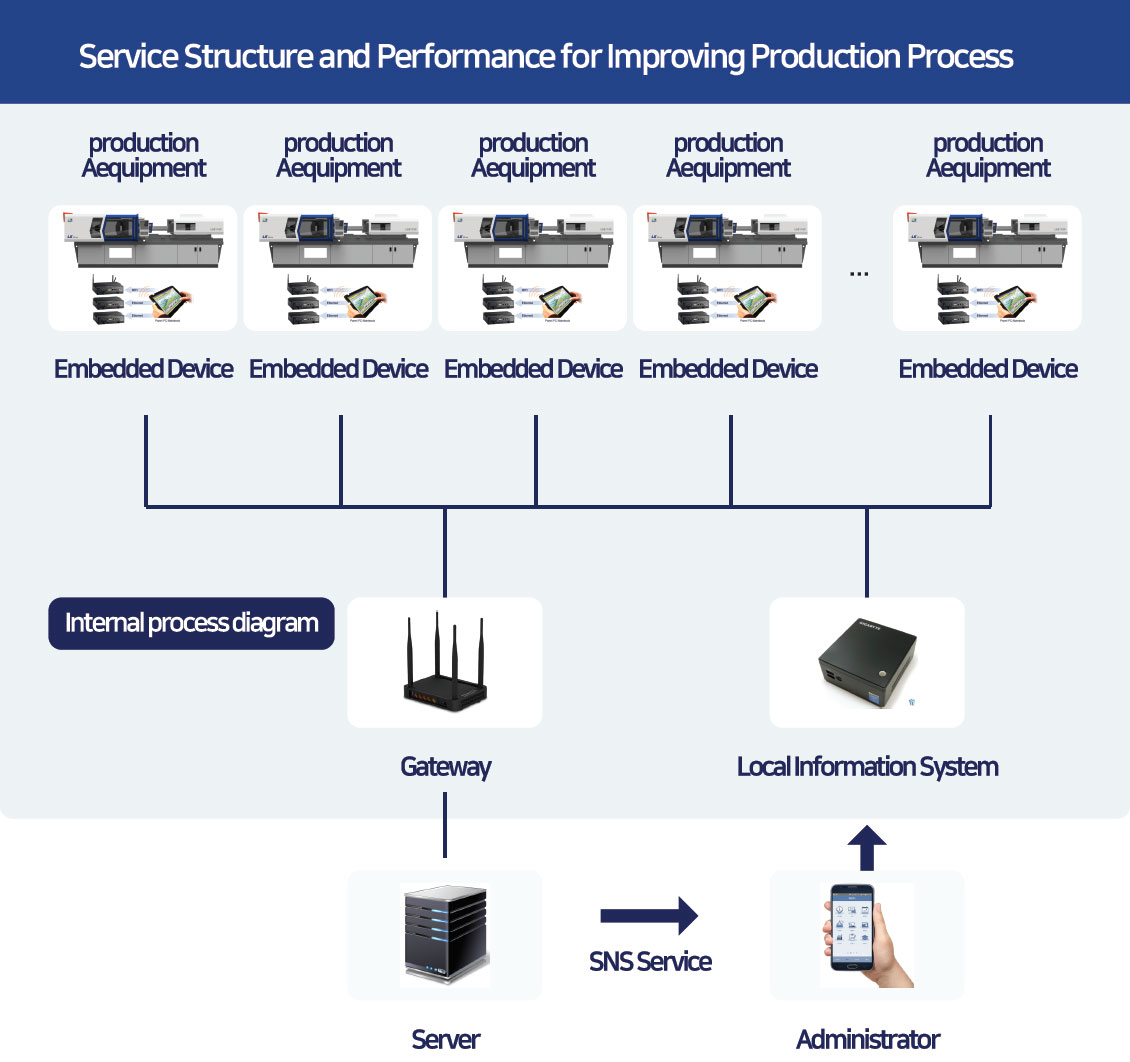

Solution Configuration

Key Features of the Solution

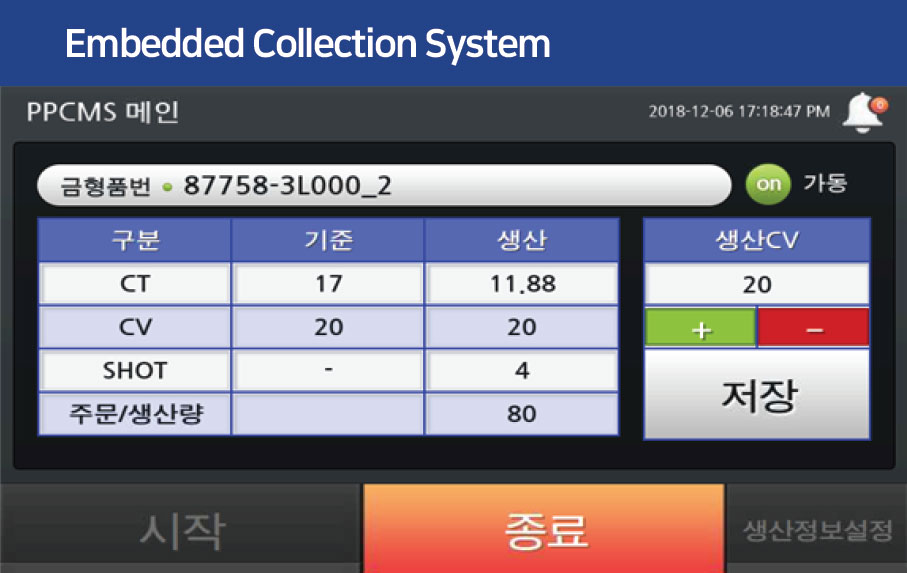

- Production/quality management support through real-time monitoring of the injection machine

- Draws out production plans and supports management indicators

- Big data analysis / prediction (part/ raw material/worktime) management support

- Performance index calculation by injection machine and mold

- Production decision making and immediate response are expedited.

- Maintaining production capacity and extracting optimal production environment

The Four Great Impacts of Solution Adopting

Solution Configuration

- Operation Movement watching and monitoring of injection equipment based on sensors

- Measurement of real-time output

- Performance index calculation by injection machine and mold

- Daily production data. production rate, operation rate calculation

- Schedule production plan through various statistical support

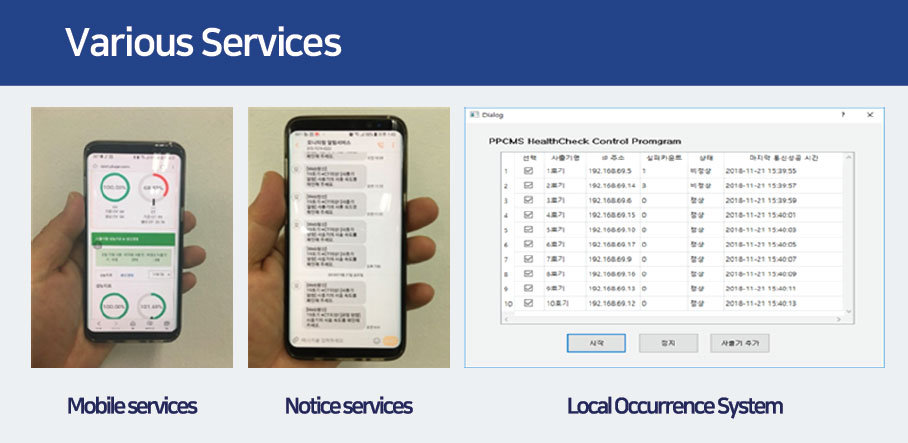

- Information using mobile devices

- Support productivity maintenance, immediate response, and history management

- System stabilization through collector monitoring

- Alarm is generated when an issue occurs through data analysis(SMS)

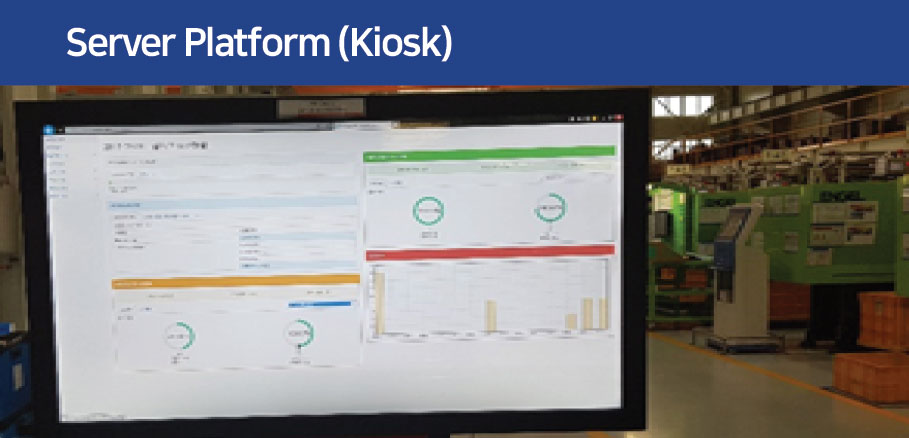

Solution Configuration Package

- PPCMS Client Module (Injector Attached)

- Server 1 for data collection

- Mobile Services

- S/W for Web Support

- Kiosk (optional)

Construction Case

- Dynamic monitoring and monitoring of injection equipment based on sensors

- Measurement of real-time output

- Performance index calculation by injection machine and mold based on collected data

- Output of daily production data of plant

Kor

Kor